This article is adapted from AQ’s special issue on the U.S.-Mexico relationship. To receive AQ at home, subscribe here.

Long considered ground zero for the decline of U.S. manufacturing, Flint, Michigan, appears to have entered a surprising new phase: recovery.

An expanding local pharmaceutical company and fresh investments in colleges and hospitals are providing new jobs. Restaurants and bars are again brightening downtown. Perhaps most encouragingly, after losing more than 70,000 jobs in the automotive sector and half of its population since the late 1970s, there are even signs of life in Flint’s factories.

“I think we bottomed out,” Sam Muma, the head of the Flint chapter of the AFL-CIO labor confederation, told me. “I see a resurgence.” He said there’s even talk the local cinema is about to reopen. “I don’t remember us having a movie theater in all my 50 years.”

Flint, and other struggling areas of the Rust Belt, were fertile ground for Donald Trump in the 2016 presidential campaign. “A lot of people — especially the auto people — are upset about where they are at in life,” said Muma. “They basically said: ‘Look, NAFTA and these trade agreements are killing us.’” On the stump, Trump hammered that message and also spoke of Flint’s recent water crisis, which made national headlines when the city government switched to cheaper supplies that proved to be poisonous.

“It used to be cars were made in Flint, and you couldn’t drink the water in Mexico,” Trump said last September. “Now, the cars are made in Mexico, and you can’t drink the water in Flint!”

That message resonated, and Trump’s victory in Michigan was critical to winning the White House. But during my month-long reporting trip to Mexico and the United States, I saw how quickly campaign slogans and bumper-sticker clichés fall apart. On the one hand, there is no question that foreign competition has played a role in the decline of Flint and places like it. One can even argue that NAFTA itself is in need of change. But there are also details like this: Quite a few of the factories driving Michigan’s incipient “resurgence” are, in fact, Mexican-owned.

Indeed, only a 10-minute drive from Flint, a factory owned by Rassini, a Mexican components company, just won a contract to make brake rotors for the Ford Mustang, one of America’s most iconic cars. Other Mexican companies in that same area of Michigan include Nemak, which is working with Ford to develop a new aluminum engine; Katcon, which makes catalytic converters; Auma, which makes engine components; Tremec, a transmissions maker; and Metalsa, which manufactures a body chassis for GM.

Luis de la Calle, a Mexico City-based consultant, said such investments have been growing since 2009, part of the complex network of logistical integration between the United States and Mexico. The connections that were initially driven by Mexico’s cheap labor and limited to a relatively narrow strip of the border area have spread geographically and across sectors. “Companies like Rassini and Nemak are succeeding in terms of the intellectual property they bring to the table,” he said.

The border is everywhere

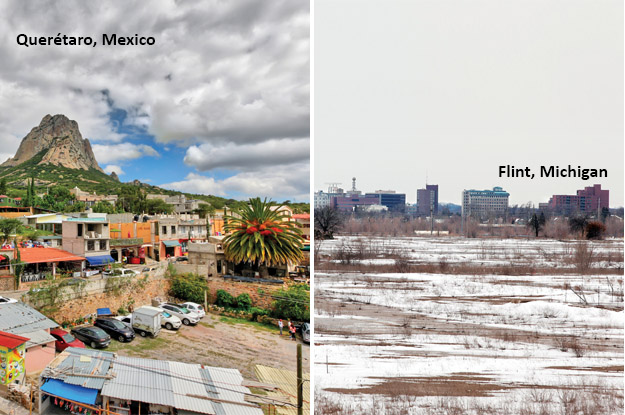

During my time on the road, I concentrated my reporting in two places geographically distant from the border itself: Flint (1,600 miles from Mexico) and Querétaro (550 miles from the United States). Yet in both spots, one sees the effects of the last two decades of cross-border economic integration — often in the most unexpected ways.

President Donald Trump visits Flint as a candidate in 2016

President Donald Trump visits Flint as a candidate in 2016

Getting the full story wasn’t always easy. My trip coincided with the turbulent first few weeks of Trump’s administration. The U.S. threat to impose a 20 percent tariff on Mexican exports prompted alarm among ordinary Mexicans and a surge in support for the left-wing nationalist Andrés Manuel López Obrador. For me it all evoked memories of the debt crises and economic turbulence of the 1980s and 1990s, when I’d first reported from the country. Many Mexican officials and companies, including Rassini, declined to talk to me, fearful perhaps that any comment they make might find its way into a presidential tweet.

Nonetheless, the cities’ divergent realities were evident enough.

Querétaro, for example, has been transformed over the last 40 years. Previously, the city was mostly confined to its colonial-era core, in many respects little changed since independence rebels used it as a headquarters in the early 1800s. But the Querétaro of today has burst out of these limits. A string of industrial parks, high-rise apartments, hotels and shopping malls lines 12 miles of the busy six-lane highway that connects Mexico City to the U.S. border.

Some of the world’s largest aerospace companies and a new university dedicated to the same industry occupy land next to a new international airport. Bombardier of Canada, Safran of France, and Aeronova and ITP of Spain have all built sizeable operations. More than 1 million people live in Querétaro, a ten-fold increase over the last 50 years. Planners say as many as 60 people a day continue to arrive in the city. While Flint is dangerous, Querétaro is becoming safer, with homicide rates less than a quarter those of the U.S. city.

“This expansion really began in the early 1970s, and in this boom, boom, boom form it has been growing for only 20 years,” said Rafael Roiz, a local businessman whose family came to Querétaro at the beginning of the 20th century. The state’s GDP has grown by an annual average of 5.4 percent over the last decade, well above the national average of about 1 percent.

Everywhere there are signs of buoyancy. Around the northern suburb of Juriquilla — the site of the city’s biggest industrial park — land values increased at “the ridiculous pace” of 46 percent in 2016, according to Victor Mena, who runs Grupo DRT, a property development company. Throughout the city there are signs advertising job vacancies, and at the Antea Lifestyle Centre, Mexico’s second largest retail shopping mall, business is healthy, with trendy international clothing brands like Zara and Forever 21 doing well. “We had a really good year in 2016, with 30 new shops opening,” said Juan Luis Durán, who manages the mall.

Flint is, of course, a different story. In the late 1960s, 70,000 people who worked at more than a dozen General Motors plants in Flint enjoyed high wages and generous benefits. But the huge factories that were emblematic of the city’s strength, such as “Chevy in the Hole” and Buick City, are now desolate scrubland. Thousands of homes disappeared, demolished by planners or burned to the ground in an epidemic of arson and looting. With its tax base slashed, the city is struggling to maintain basic services. Whole districts of the city are a depressing wasteland of boarded-up shops and public buildings, with only liquor stores and fast food joints open for business.

With fewer police officers to secure order, crime rates have soared. Forty-seven people were murdered last year, making Flint’s homicide rate among the highest in the Americas. “It is a real disaster,” said Scott Kincaid, a former tool and die maker at General Motors and now a trade union official and member of the city council. “When you cut services, you cut out what people want and they find another place to live, and that’s what you are seeing in Flint.”

“Little to do with NAFTA”

The obvious conclusion would be that Flint’s decline and Querétaro’s rise are related — that one wouldn’t exist without the other.

But delve a little deeper and the reality begins to look more complicated.

To begin with, Flint’s problems were well advanced by the time Mexico began to open up its economy in the mid-1980s. The energy crisis of the 1970s was a crucial turning point, with oil price rises devastating the GM business model of making large, gas-guzzling automobiles. Heavily unionized plants were slow to react to new trends, with the smaller, more fuel-efficient cars of Japan and Europe gaining ground.

An auto plant in Flint

An auto plant in Flint

As early as 1984, Michael Moore, the filmmaker whose popular film Roger and Me brought Flint’s problems to the attention of a wider public, wrote an obituary his native city. That was two years before Mexico joined the GATT, the forerunner of the World Trade Organization — and a full decade before the U.S., Mexico and Canada signed NAFTA.

Developments in Flint’s auto industry were part of a broader trend in manufacturing, with job losses and productivity rising — mostly as a result of automation. “The trend had little to do with NAFTA,” said Phil Levy, a senior fellow on the global economy at the Chicago Council on Global Affairs and a former adviser to President George W. Bush. According to a recent study by researchers at Ball State University, 85 percent of the 5.6 million job losses in U.S. manufacturing from 2000 to 2010 resulted from technological changes, as opposed to trade.

Meanwhile, as international competition has increased and products have become more sophisticated, the nature of manufacturing has changed. Rather than being integrated in one city like Flint, the production of components and assembly has been broken down and become more specialized. Many lower-skilled operations moved toward countries — such as Vietnam, China, Poland and the Czech Republic, as well as Mexico — that have lower wage levels. In the car industry, Mexican wages are between a fifth and an eighth of U.S. levels, according to a recent study by the Ann Arbor-based Center for Automotive Research.

At the same time, the more customized design and engineering processes are moving toward countries where it is easier to find designers and engineers. In some cases, businesses are choosing to be nearer their final customer. In other processes, parts sometimes need to be modified to meet the needs of particular customers and often at relatively short notice.

One example is Firstronics, a rapidly growing Grand Rapids, Michigan-based company, that designs and makes circuit boards for LED lights, gear controls and fuel pump controls for customers in the car, lighting and medical devices industry. Its circuit boards — formed by injecting copper wiring into fiberglass boards — are customized to meet precise requirements of fast-moving industries, so it has proved beneficial to have facilities that are physically close to customers. For that reason the company has plants in Mexico, Poland and China as well as Michigan. “The ability to source in Mexico benefited the U.S. plant as well,” said John Sammut, the chief executive.

“Nowhere else do you find (the numbers) of U.S., German, Japanese and Korean companies as you do in (the) Detroit (area),” said Kristin Dziczek of the Center for Automotive Research. “The car companies have to come to (the Detroit area) because their suppliers are here and the suppliers (have to come) because their customers are here. It is a very international marketplace.”

Good governance in northern Mexico

In Querétaro’s case, NAFTA has certainly been a major factor in the city’s rise. But so have government policies that don’t get a whole lot of publicity in the United States — or, for that matter, in Mexico itself.

For example, the Mexican federal government’s commitment to free trade goes well beyond just NAFTA. Exports from Mexico to 44 countries are exempt from tariffs, which has made the country an export base in sectors like medical services and capital equipment, as well as cars and aerospace. The government’s energy reform, which began in 2013 and broke up state monopolies, has also enhanced its attraction. The provision of cheap piped gas from Texas shale fields means energy costs have fallen by more than 70 percent. According to De la Calle, this will allow the country to step up its production of energy-intensive basic goods, ranging from steel to plastics.

Meanwhile, since Mexico’s political system began to move away from one-party rule in the 1980s and 1990s, the quality of state and local governments has varied more widely. Some states are caught in the clutches of drug gangs and other organized crime. But in Querétaro and other states of a northern region Mexicans call the Bajío, government has been relatively clean and effective.

The National Aerospace University in Querétaro

The National Aerospace University in Querétaro

Good governance was critical to the birth of the city’s aviation industry. The decision by the state government in 2005 to build an international airport helped persuade Bombardier, the Canadian aircraft maker, to establish a factory in Querétaro in the same year. Bombardier was also tempted by the government’s offer to train workers on its behalf.

The city and state now boasts not only 14 engineering colleges, but an entire university — the National Aerospace University of Querétaro, or UNAQ — dedicated to the industry. Based in an aircraft hangar a stone’s throw from the airport, and containing aircraft and components donated by the companies themselves, the facility teaches what Jorge Gutiérrez, its rector, described as the “reality of aircraft manufacturing” to college-level, degree-level and post-graduate students.

“We help the companies reduce their development curve,” Gutiérrez said, referring to the time they take to bring products to commercial viability. “When their plants open they’ll have (workers) and their takeoff times will be very short. If the institution didn’t exist this process would be twice as long.”

This network of education facilities is scheduled to expand later this year when the University of Arkansas opens a college in Querétaro — the first time a foreign university has done so in Mexico. The availability of skilled labor is an important attraction in bringing international companies to the city. Safran, the French component maker, is one of the largest, employing almost 2,000 people in the city.

Shared prosperity

So what was my conclusion from all this reporting? I actually flew back home from Michigan feeling somewhat optimistic about the prospects for NAFTA.

That might sound surprising. After all, I found plenty of examples of businesses that would be hit hard if President Trump were to actually implement a 20 percent tariff on Mexican imports, as he has threatened.

Consider the case of Jatziri Barrios Porras, who in many ways personifies her city’s embrace of high-tech engineering — she told me she “fell in love with engine propulsion” while studying in Germany. Today, she is developing a small aerospace unit in Querétaro. She confessed that tariffs “would break down my entire business case.” The highly machined landing gear parts and low-pressure turbines her company is making must cross the U.S. border four or five times to undergo rigorous tests. Querétaro’s businesses are anxious to develop these capacities closer to home, but so far local companies lack the know-how and — crucially — the financing.

But it is this same density of connections between manufacturers on both sides of the border that provides some reason for confidence. In the auto sector, U.S. and Mexican businesses have become entwined, especially since the financial crisis of 2009. At least 40 percent of Mexican exports to the U.S. contain parts made in the United States.

Officials at development agencies suggest that these linkages are advancing, notwithstanding the political uncertainty. Witness the recent decision by the Detroit chapter of the U.S.-Mexico Chamber of Commerce to reopen its doors, or the fact that in the first four months of this year the Michigan Economic Development Corporation was organizing two separate trade missions to Mexico.

All these connections seem to suggest that whatever its faults, the real impact of NAFTA has been not to deplete or undermine U.S. manufacturing, but to create a framework in which North America as a whole can compete more effectively with Asian and European rivals. Maybe, in the long run, it is possible for Flint and Querétaro to prosper together.

Photo credits:Mandel Ngan/AFP/Getty; Jeff Kowalski/Bloomberg/Getty; Christian Rodriguez/Bloomberg